AGO stands for “Another Great Opportunity”. This was probably his first thought when the Italian Francesco Rampichini discovered a new adhesive in 1911. With the AGO adhesive, it was possible for the first time to bond leather to leather, which revolutionized shoe manufacturing. Of course, Rampichini’s adhesive has been further developed over the decades. Today, it is a high-tech product that is also used at the HAIX headquarters in Lower Bavaria.

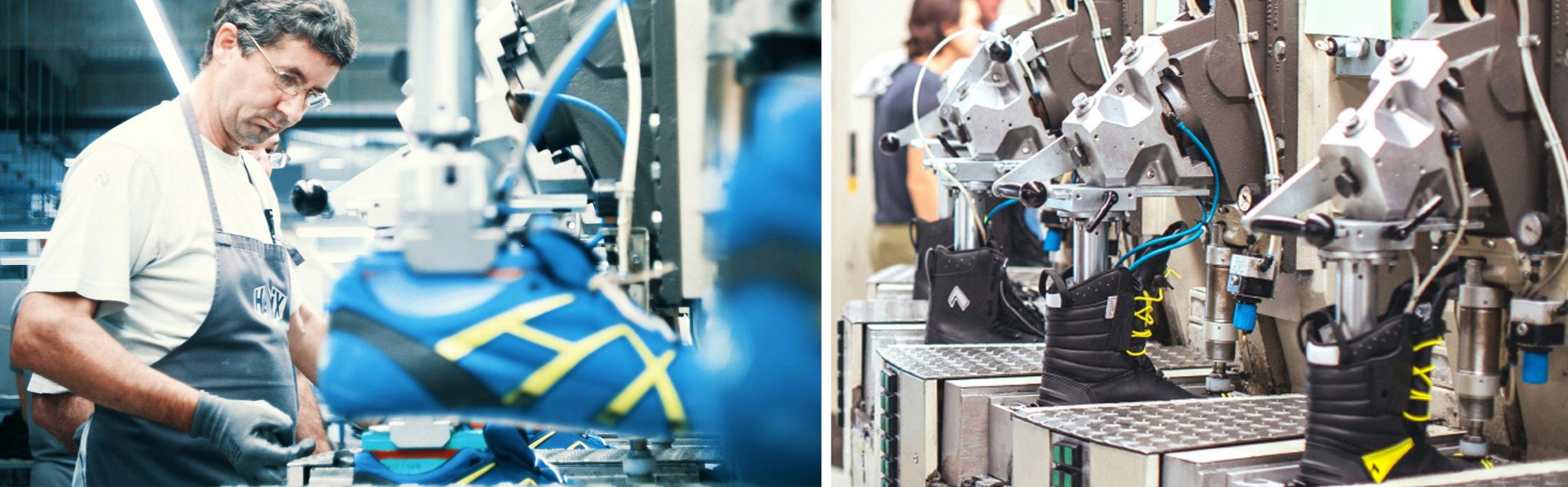

The history of Rampichini’s glue represents a philosophy of HAIX: tradition and high-tech are not mutually exclusive. Although the AGO manufacturing method has been cultivated in the shoemaking trade for over a hundred years, HAIX combines it with the most modern machines and materials to produce innovative shoes.

With AGO, it works like this: First, the upper and lining are pulled over a last and pinched to the insole. This upper is then glued to the shoe sole. The result is a light, stable and robust shoe.